Have specific

conditions in mind?

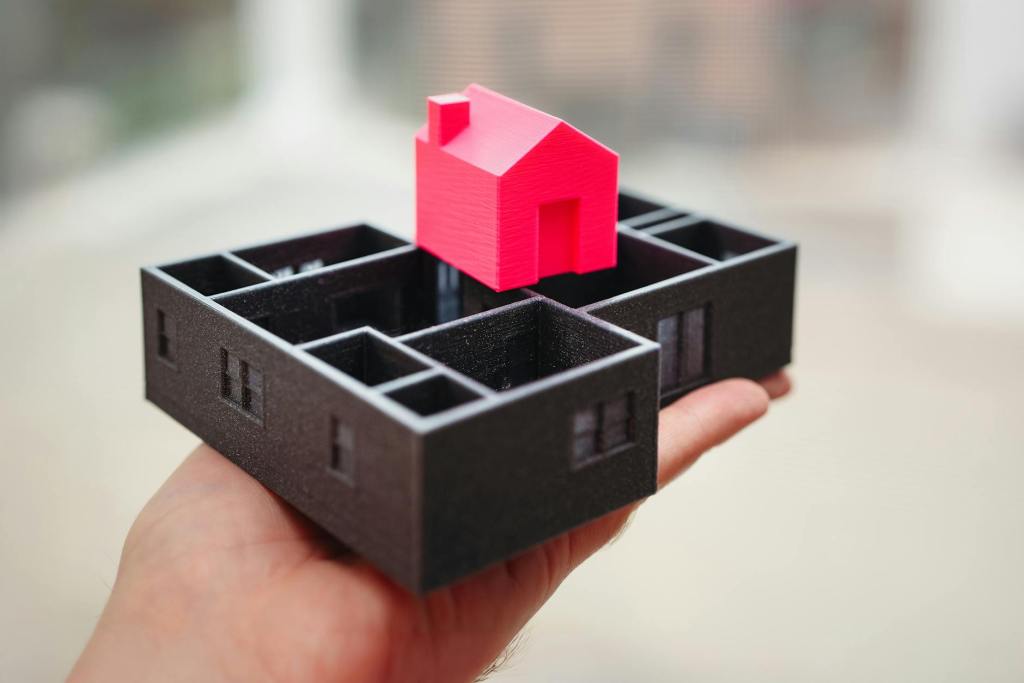

Not to worry! We provide a wide variety of options to make your vision a reality.

Materials

Whether you’re looking for strength, flexibility or durable environmental resistance, our versatile selection ensures the perfect material to bring your projects to life with ease and confidence:

Every material is available in standard black or white. Custom colours available for +$2/colour per order.

PLA: A lightweight and rigid material, perfect for decorative pieces, prototypes, or low-stress everyday items. An excellent choice for designs that prioritize appearance over function.

PETG: A durable and moisture-resistant material that offers a balance of strength and flexibility. Perfect for creating robust parts that need to withstand wear and exposure.

ABS: A tough and heat-resistant material built for strength and durability. It’s ideal for making tools, enclosures, and functional components designed to endure impact and challenging environments.

ASA: An exceptionally weather-resistant material, known for its UV protection and strength. Best suited for outdoor applications like housings, signage, and other components that must handle prolonged exposure to sunlight and the elements.

TPU 68D*: A semi-rigid, flexible material that combines durability with slight elasticity, making it ideal for functional parts where flexibility is essential but rigidity is also required.

*68D refers to the shore hardness of the material. Make sure this supports your application.

Printing Settings

While we offer basic templates (see below), advanced users are welcomed to tweak the printing parameters to their exact preferences

Resolution (draft, standard, high): 3D printing works by depositing material one layer at a time. Lower resolutions reveal more of these layer lines. Higher resolutions conceals them better but increase price due to a slower print.

Detail (standard, high): Big and/or simple parts will usually function perfectly at standard detail. However, smaller more intricate parts will often benefit from more detail at the cost of a higher price.

Strength (low, standard, high): 3D printed parts are partly hollow (infill) which saves on weight and material costs. Infill is defined as a percentage of occupied space with 0% being fully hollow and 100% being a solid part. This number along with the thickness of the walls (solid space between the outside of a part and the start of the infill) determine the final strength.

Texture (textured, smooth, fuzzy): Contrary to other manufacturing methods, 3D printing can accentuate your parts with texture with no additional cost! Textured vs smooth refers to the bottom surface of your part while fuzzy adds texture to the outer walls if desired.

Feel free to email us at info@curiose.ca for questions regarding these settings or additional preferences.